Microchips embedded in RFID tags can track and authenticate vaccines, test kits, medical equipment and PPE from manufacturing to clinic sites.

Radio-frequency identification (RFID) technology made a comeback in recent years, in retail, airline logistics and baggage tracking and in healthcare.

Now it’s being used in the fight against COVID-19.

Microchips embedded in RFID tags can track and authenticate the vaccine journey from manufacturing to clinical site, along with antibody test kits, personal protective equipment (PPE), medical equipment and high value drug treatments.

RFID is even monitoring some healthcare clinicians’ use of hand-washing equipment.

The technology has widespread applications in medical supply chains, and its ability to track and transfer data in real time helps managers maintain visibility during the rapidly changing coronavirus pandemic.

- RFID authenticates test kits and PPE

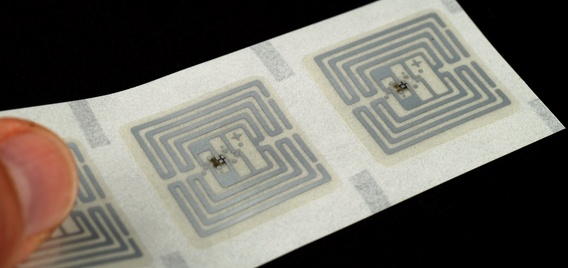

Blockchain company SUKU partnered with Smartrac, an Avery Dennison company, to digitally verify and authenticate COVID-19 test kits and PPE using a near field communication (NFC) RFID tag. The data feeds into Avery Dennison’s Digital Identity Platform, which integrates with SUKU’s blockchain-based supply chain application.

Blockchain company SUKU partnered with Smartrac, an Avery Dennison company, to digitally verify and authenticate COVID-19 test kits and PPE using a near field communication (NFC) RFID tag. The data feeds into Avery Dennison’s Digital Identity Platform, which integrates with SUKU’s blockchain-based supply chain application.

The tags allow the test kits to be authenticated as Food and Drug Administration (FDA)-approved and from a legitimate source. The HIPAA-compliant platform also provides test results, which clinicians with permission can access for greater visibility. The platform can identify COVID-19 hotspots, Amir Khoshniyati, NFC business lead at Avery Dennison, told Supply Chain Dive.

The partnership supplies approved vendors with the NFC RFID tags to use on specific products like test kits. If a manufacturer receives 10,000 tags, it has factory control and traceability over those kits, Khoshniyati said. If there’s an overrun of 1,000 kits, the extra kits are still authentic but won’t have NFC tags. The tags are a way to control distribution and identify who is allowed to sell the items.

Smartrac’s near field communication RFID tags allow test kits to be authenticated, and the data feeds into a platform that provides test results.

Smartrac’s near field communication RFID tags allow test kits to be authenticated, and the data feeds into a platform that provides test results.

Smartrac While COVID-19 test kits are tagged individually, PPE products are more often tagged at the box or carton level, Khoshniyati said.

The tags authenticate PPE’s product origins and contain pricing information. Because it’s blockchain, “no one can modify that. It can’t be manipulated by any party,” Yonathan Lapchik, SUKU CEO, told Supply Chain Dive. This combats some of the issues seen with questionable origin and counterfeiting. “By selling tags to these approved suppliers, you can track where they come from, generating information for the buyer, like at what price the PPE should be sold at, and if they’re authentic,” Lapchik said.

Experts predicted that as RFID technology matured it would be a natural fit for supply chain blockchain applications. The combination of the two enhances visibility and reduces errors by removing the human factor from the equation.

The platforms do not necessarily need to integrate with company systems, Lapchik said, and so far customers haven’t wanted to integrate them, though that may happen as the pandemic continues. Users can view the data without additional software by tapping their smartphones close to the test kit or PPE label.

- Real-time visibility for plasma and vaccines

Several companies are using sensor RFID technology to track plasma, some of which is used in treating COVID-19 patients.

In June, Biolog-id announced it was supplying RFID tracking of convalescent plasma for LifeShare Blood Center in the south-central U.S. This plasma is collected from patients recovering from COVID-19, to provide antibodies to patients fighting the disease. The technology provides real-time visibility from collection to distribution, Biolog-id said in a press release.

“Can’t be manipulated by any party.”

Yonathan Lapchik

CEO, SUKU

Vaccines are not currently equipped with dose-level tracking, Mahesh Veerina, CEO of Cloudleaf, an IoT sensor and visibility company, told Supply Chain Dive. COVID-19 accelerated the digitization efforts for vaccines and supply chain tracking, he said, given the billions of anticipated vaccine doses needed.

ApiJect Systems America, a packaging manufacturer contracting with the government, is offering space for an NFC RFID chip on individual prefilled syringes, it said on its website. The chip links to a health worker’s phone, and administrators can remotely track each injection in real time.

RFID technology and blockchain tracking ensure vaccines are not counterfeit or tampered with, and they verify the chain of command. Sensors can also verify that vaccines are sent to the designated countries and locations, with information reported back to the World Health Organization, Veerina said.

- Hospital monitoring, from inventory to hand-washing

While not COVID-19 specific, RAIN RFID, another sensor technology, is using the technology in multiple ways inside hospitals. Hand-washing hygiene is always an important directive in healthcare, but during a pandemic, it’s even more important.

“RAIN RFID is making it more feasible for hospitals to ensure compliance of staff with hand-washing protocols,” Sandy Murti, VP of global partner development at Impinj, told Supply Chain Dive. An RFID reader at a hand-washing station can read a badge or tag on a healthcare worker’s uniform. Management can use the information to track when and how often the person is washing their hands.

RFID tags in hospitals can track medical equipment without workers having to touch assets or manually inspect them.

RFID is used more frequently in hospitals to track durable medical equipment and other high value assets. “It does so without having to touch the assets or manually inspect them,” Murti said. Staff can quickly locate the equipment in the hospital, as fixed RFID readers throughout the facilities can track the equipment’s movement and location.

RFID tags are also used to track consumables like medications or higher value supplies. “The low cost of labels used in high volumes can be treated as throwaways, affixed to medical supplies. They help with a more accurate inventory supply level in a hospital, and help optimize use of the supplies, to put them where they’re needed, and to replenish them if getting too low,” Murti said.

The RAIN RFID tags are also popular with hospital linen services, so staff don’t have to manually count linens when they leave and arrive back at the hospital after cleaning.

[RFID tags] help with a more accurate inventory supply level in a hospital … to put them where they’re needed, and to replenish them if getting too low.”

Sandy Murti VP of global partner development, Impinj

Companies choose RFID options based on need. Scanners can read hundreds of RAIN tags within seconds at a distance of 10 to 30 feet. NFC tags have a more limited use case, according to Murti, because single tags are read at once and over a shorter range.

“The level of interest from hospitals and their partners in using the technology has been increasing as a result of pressure in the supply chain overall,” Murti said. “For hospitals using the technology, they might start with tracking one category of items, like high value medications. As they get more comfortable with its use and effectiveness, it’s not uncommon to see adoption spread to other types of supplies and assets.”

Story from Supply Chain Dive.